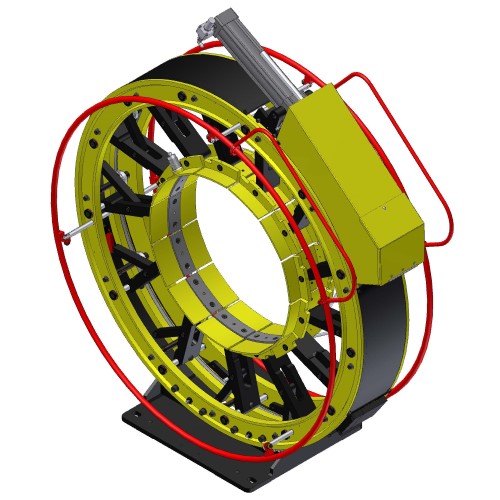

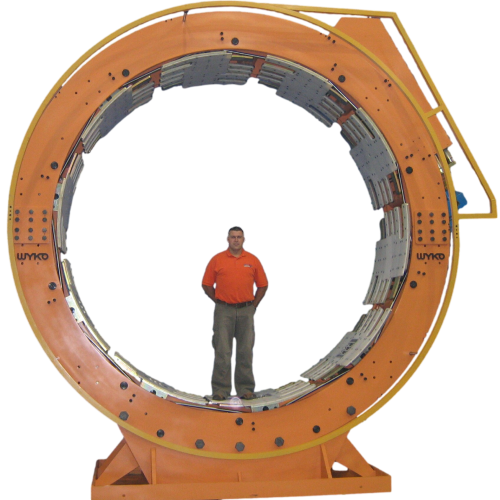

Transfer Rings / O-Rings

Transfer Rings – or O-Rings – serve a crucial role in the tire building process. By grasping the Belt/Tread (BT) package and placing it over the carcass for consolidation, one could say this is where it all comes together. The accuracy and repeatability of this step has far-reaching impacts on the final outcome of the tire. Yet, some manufacturers overlook this critical part of the process and battle sub-optimal quality/yield using inferior equipment.

At WYKO, we understand the importance of every detail, which is why we go above and beyond in the design, manufacture, and controllability of every Transfer Ring. Our tooling provides optimal roundness and concentricity while offering uniform contact pressure across a variety of shoe/segment quantities available.

Higher Range. Higher Shoe Count. Higher Performance.

Our best-in-class Transfer Rings are well-known for their exceptional reliability, outstanding service life, and ease of maintenance owing to fewer moving parts. What’s more, they can achieve the entire building range without the need for any size changes or adjustments.

WYKO O-Rings are easily integrated into your new or existing machines with numerous mounting styles, control options, and safety components available, all to provide you with a superior plug & play solution.

Available in all sizes from passenger to giant OTR, including built-to-suit solutions.

Features

- Extremely high working diameter range

- Actuation via servo-electric or pneumatic (hydraulic available for AG, OTR)

- Various selection of shoe/segment quantities – typically prime numbers (17, 13, 11,)

- Lightweight models available

- Wide variety of mounting options including overhead and side-mount

- Custom shoe/segment configurations

- Can be designed to incorporate other machine elements such as finished tire removal, bead set/turn-up, etc.

Benefits

- No size changes or adjustments required for most ranges

- Improve uniformity – reduce harmonics

- Robust design, precision machined for optimal roundness

- Consistent radial contact pressure throughout range

- Fewer moving parts, ease of maintenance

- Highly adaptable, easily customized for your process requirements

- Long life

Options/Upgrades for Transfer Rings / O-Rings

- Servo-Actuation – provides maximum control, efficiency, and eliminates unnecessary movement

- Shoe/Segments:

- Profiled: convex, concave, interlacing, progressive edge (patent pending)

- Spikes/Seizing Nails

- Coatings

- Magnets

- Vacuum

- Spacers/inserts

- Lightweight models (primarily aluminum construction)

- Safety: Edge sensing devices, light curtains, scanners, bump bars

- Wide array of sensors for process control

- Associated equipment:

- Stationary/fixed base

- Bead setting / turn-up

- Stitching

- Green Tire gripping / retrieval