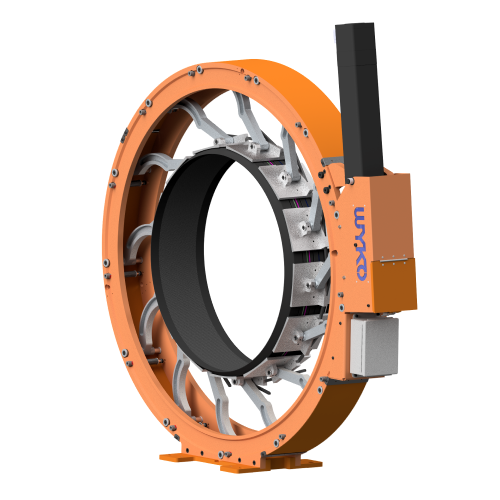

WYKO High-Range Cam Link™ Transfer Rings/O-Rings

The latest generation of High Range Cam Link™ Transfer Rings has raised the bar… again! WYKO’s patented Cam Link™ technology brings incredible range and flexibility to your operation.

First introduced in 2010 as the premier alternative to our proven “scissor-link” models, WYKO’s Cam Link Transfer Rings have continually been enhanced for maximum functionality, adaptability, and service life.

The proven Cam Link design is a culmination of channeling years of industry experience, customer feedback, and innovative engineering into a robust solution with no compromises.

At the heart of the design is the Cam Link itself. The Cam Links are specifically engineered for each model/size, resulting in approximately one-third less actuation force required as compared to other linkage-style Transfer Rings.

This contributes to the smooth operation and long life of internal components by virtue of loads and actuation forces being more evenly distributed and consistent throughout the operating range. Additionally, this eliminates the need for secondary brakes/locks commonly required on competitors’ transfer rings.

Tight on space? Thanks to the Cam Link system’s inherently compact design and ‘range density’, our engineers can utilize available space within your machines to provide you with maximum operating ranges.

13-Section Cam Link™ Transfer Ring/O-Ring

As the standard in our Cam Link series, 13-Section models (13 shoes) provide exceptional working diameter ranges and virtually hands-free service.

Features

- Servo-electric or pneumatic actuation (hydraulic available for AG, OTR)

- Patented Cam Link™ technology

- Lightweight models available

- Wide variety of mounting options including overhead and side-mount

- Custom shoe/segment configurations

- Can be designed to incorporate other machine elements such as finished tire removal, bead set/turn-up, etc.

Benefits

- Extremely high diameter range – no size changes/adjustments

- Improved uniformity – reduced harmonics

- Robust design, precision machined for optimal roundness

- Consistent radial contact pressure throughout range

- Fewer moving parts, ease of maintenance

- Highly adaptable, easily customized for your process requirements

- Long life